Global - Engilsh

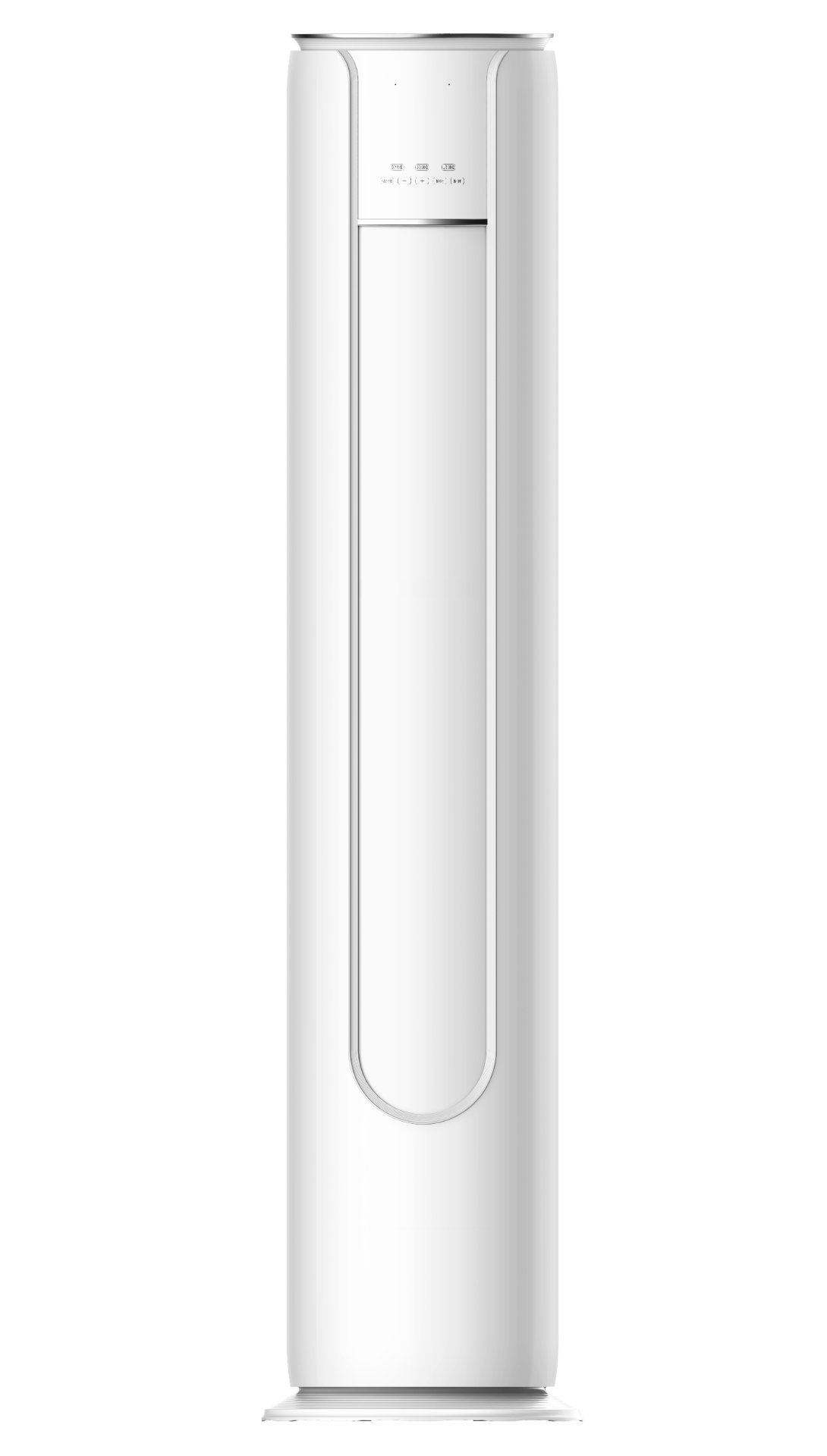

I. The Intelligence of Air Supply Systems

"Airflow follows sound," precise positioning, achieving both energy efficiency and living comfort

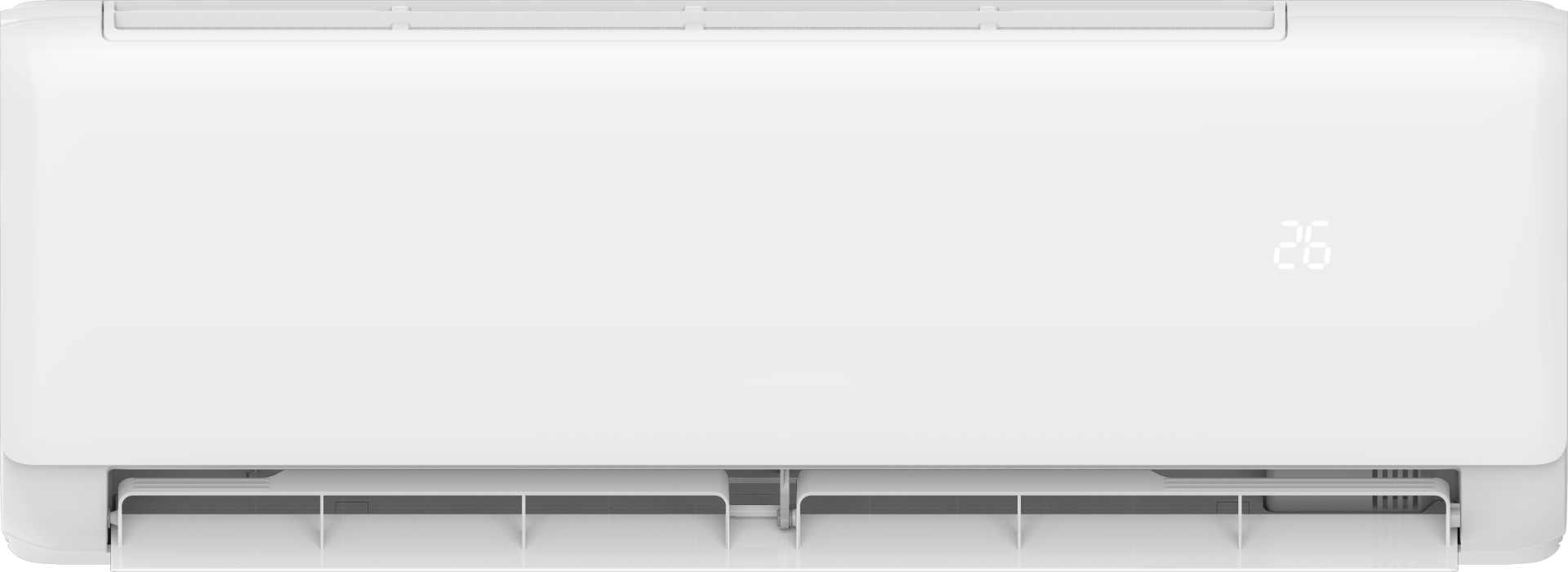

As a pivotal breakthrough in AUX Core Air Conditioning Technology, we have revolutionized traditional air supply modes. By integrating high-sensitivity sound source localization and infrared sensing technology, the system identifies human position and activity status in real-time, achieving intelligent air supply where "airflow follows movement, airflow avoids stillness."

The system intelligently adjusts wind speed and precisely manages the direction of airflow, delivering comfort only to occupied spaces and avoiding energy waste. This efficient targeting, powered by Inverter Air Conditioning technology, creates an "active comfort" experience—where seamless energy savings and consistent, personalized comfort are equally evident.

II. The Strength and Resilience of the Core Chip

Stable operation in cold, unwavering efficiency, challenging the limits of low-temperature energy saving

In a simulated harsh low-temperature environment of -25°C, supported by advanced Smart Technology and independently developed low-temperature compensation algorithms, our air conditioning system maintains stable heating efficiency throughout. The chip’s built-in dynamic frequency modulation control not only breaks through traditional heat pump bottlenecks but also significantly enhances Inverter technology efficiency, ensuring unwavering performance even in extreme cold.

Through its precise coordination of the electric heater system, the AUX core chip is the key to a highly effective heating system. It only grows more efficient as the cold intensifies—the core remains "stable as ever," delivering consistently excellent energy savings and reliable warmth to users across the globe, regardless of the frost.

III. Precision in AUX’s Manufacturing Processes

Powered by intelligent production lines, precision engineering, reducing energy loss from the source

As the Air Conditioning Industry Leader AUX, we rely on fully integrated Intelligent Manufacturing production lines to achieve high-precision control and automated collaboration throughout the process. Precise machine assembly and real-time correction by visual inspection systems significantly reduce the uncertainty and errors associated with manual operations.

Simultaneously, through material optimization and friction loss design, operational resistance of key components is lowered. This pursuit of lean manufacturing not only enhances product consistency but also achieves long-term energy saving right from the source.

From intelligent airflow control and chip cold resistance to the rigorous standards of Intelligent Manufacturing, we construct a complete closed loop for energy efficiency. AUX is committed to unlocking energy-saving potential at every technical stage, creating a truly power-saving, reassuring, and comfortable future living experience for our users.